Die Idee detailliert Ausarbeiten

THE CREATION OF A HANDBAG

AN IDEA

Each bag begins with an idea, a first creative thought that marks the beginning of a long, laborious development process. Sometimes it is a shape that sparks inspiration - a sculpture, an object, a detail seen in the nature. Or it is a task, such as to create a backpack, which can also be worn as a bag. Frequently, the beautiful leathers themselves serve as a starting point for new model developments; when you touch the soft skins, let them flow through your hand, move them to feel their character, then vague ideas pop up in your head. One can never force creativity – luckily, as a designer one never really ceases to work, the creative mind always collects impressions, inspirations or fragments of ideas. At GRETCHEN they are collected in a large “archive of inspirations” in the form of photos, scribbles and sketches. So some ideas ripen over months or even years before they are transformed into a wearable bag.

PLAYING WITH THE INITIAL IDEA

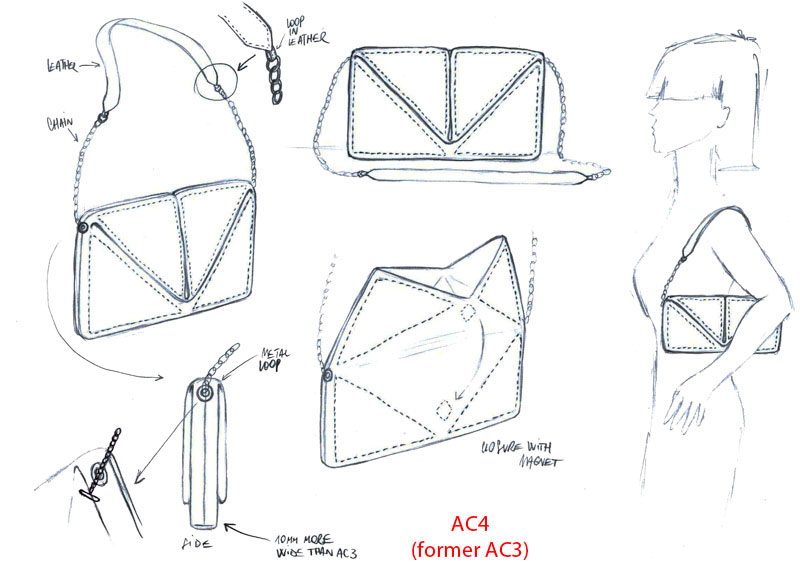

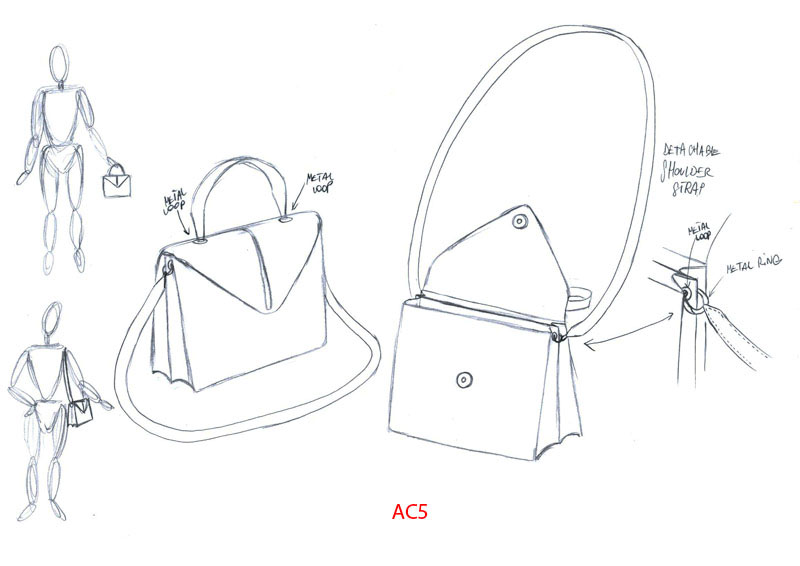

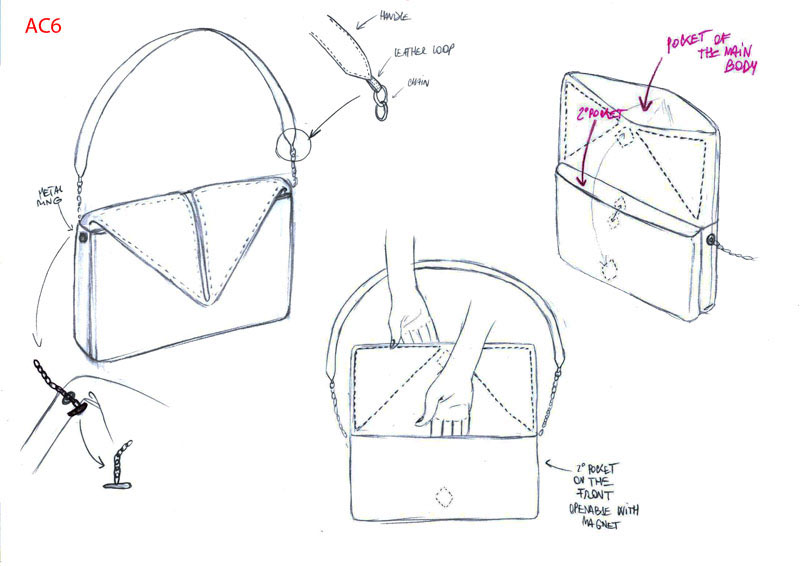

Once the first idea for a new bag is formed, the “playful phase” begins. At first numerous sketches are made on the paper; manifold variations of the same idea are tried out this way. Should the bottom be rounder or rather more tapered? Are two short handles more beautiful or a long one just more practical? Or should the bag have both? This process takes days and weeks to complete - in very rare "lucky cases" perhaps only a few hours.

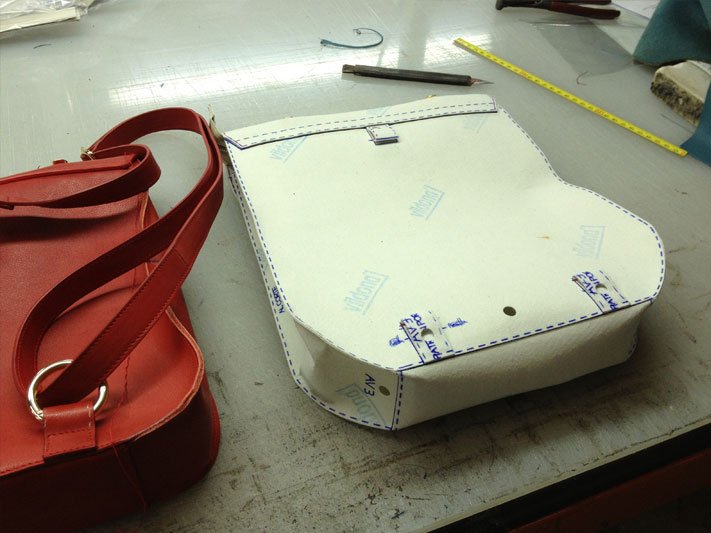

Out of the multitude of variations, the best ones are filtered out and roughly built in paper or cloth as a “dummy” to get a better feeling for their size and proportions. Thereafter, the dummies are again critically examined - is the shape harmonious? Or should it be a little wider, the bottom perhaps a little deeper to allow for more volume and storage space? Is the opening big enough for the bag? How does the bag work in its overall aesthetics? Even in this pre-development stage, often four, five, six 3-D paper patterns are created until everything is optimal and the result "feels right".

At GRETCHEN, we call the final dummy 'Pre-Proto', serving as the starting point and reference for the actual sample development, though little more than a vague image of what will finally become a leather handbag.

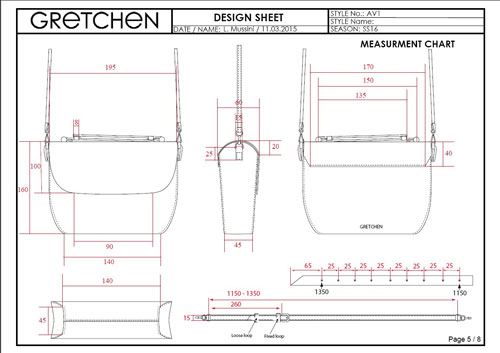

WORKING OUT THE DETAILS

With the Pre-Proto in hand, the so-called ‘design sheet’ is now written down, serving as "construction template" for the first leather prototype. In this design sheet, numerous views (front, back, side, top, bottom, inside) are drawn, together with as much detailed description as possible to pass on all relevant bits of information to the pattern maker who will then develop the actual cutting patterns: dimensions, cuts, any finishing details (positions of buckles, how they are fixed), which type of seam goes where, reinforcements (where and which?), materials, fittings. It is like the step-by-step construction manual which - together with the pre-proto and all the components for the first prototype - enables the creation of the first pattern. Detailed technical aspects about the construction are then discussed and evaluated together with the sample maker. During the course of this discussion and pattern development, small modifications and changes often already take place in order to improve the construction: a more precise and thought-out construction, maybe a more appealing detail-solution, a reinforcement that will improve the durability of the bag. At this stage the creative idea are paired with the life-long experience of the pattern- and sample-makers to enable the crucial step from an idea on paper into a real object.

FINALIZING THE DESIGN

The creation of the first prototype is always exciting, thrilling and often surprising - even after years of designing. The proto can turn out surprisingly good, surprisingly different, sometimes not as expected, despite all the preliminary work. An idea can look good in paper - whether it works in leather shows only with the real prototype. The latter gets meticulously analyzed down to the last detail and tested for appearance and functionality, dimensions and workmanship, sometimes even partially disassembled to test whether another reinforcing material behind the bag gives a more beautiful overall look. Or if the design should be crafted from a different leather.

Adjustments are discussed in detail and recorded before a second prototype is made. Again, the second prototype undergoes the same review process, is critically analyzed, discussed, and tested. Depending on the complexity of the design idea and its technical requirements, a third and even fourth prototype are developed, because only when the bag meets our expectations and requirements 100% and is worked out in detail does it receive its final approval for production. Then the paper cutting patterns are mounted onto a solid cardboard so they are stable enough for production. A meticulously detailed work description is written up, in which every little manufacturing step is recorded to make sure that in production, the bags will be produced exactly the same way as the final prototype.

Depending on the design idea, it takes three to five months and sometimes even longer before the very first idea has been turned into a "finished" GRETCHEN bag. And only then will the color options be planned, all necessary materials such as leather, fittings, zippers and yarns ordered before we start producing a new handbag model for our customers.